Middlebury College Winter Term 2016

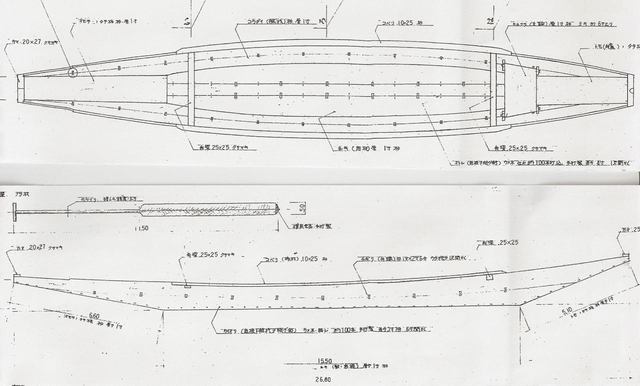

Mr. Hideto Hatano, a researcher on the history and culture of the Agano River, supplied our drawing. He measured one of the river’s boats after the last boatbuilder of the region passed away.

In 2016 I taught my third Winter Term at Middlebury College, my second class entitled “Building the Japanese Boat.” In this course I led sixteen students in the construction of a 27-foot river boat from the Aganogawa in Niigata Prefecture, Japan. This course introduces students to the tenets and principles of apprentice learning through readings, lectures, discussions and through building a traditional Japanese boat. The course meets four days a week for one month. I do not require students to have any prior woodworking experience. Students keep a journal which I periodically review and write a final paper for the class. I grade them on their comportment as apprentices in the workshop and the quality of their final paper.

I have chosen to build river boats because these designs are more straightforward and therefore more practical given the short time frame and the students' lack of woodworking experience. Most of my students have never done any woodworking whatsoever, but by the end of the class they know how to sharpen hand tools, adjust and tune planes and chisels, and have mastered using specific Japanese boatbuilding tools like the tsubanomi and boatbuilding saws.

The course ends with a Shinto launching in the College swimming pool. Outdoor temperatures are typically well below freezing.

I blogged about the project here: http://blog.douglasbrooksboatbuilding.com/2016/02/2016-middlebury-college-winter-term.html

© Copyright Douglas Brooks, 2007 - 2018. All rights reserved